- Visibility 48 Views

- Downloads 11 Downloads

- DOI 10.18231/j.jco.2024.044

-

CrossMark

- Citation

Impact of recycling on efficiency and efficacy of copper nickel titanium wire and heat activated nickel titanium wire – An invitro study

- Author Details:

-

Nibha Yadav

-

Piyush Bolya *

-

Vikas Goyal

-

Shuchi Singh

-

Neha Ajmera

Introduction

Nickel-titanium (NiTi) wires have been preferred by clinicians in comparison to stainless steel wires as they have a wider working range and higher springback properties.[1] Recent advancement has been done by adding copper to nickel titanium wires to increase temperature control, springback, and deformation resistance.[2], [3]

Copper Nickel–titanium (CuNiTi) alloy wires and Heat activated Nickel- Titanium (HANT) alloy wires gained popularity because of their properties like superelasticity and shape memory.[4]

These properties make the wires resistant to permanent deformation so that the wires return to their original shape after clinical usage.[5], [6] The relatively high cost of copper nickel-titanium wires and this ability to return to their original form has led to their reuse. This raises concerns about the treatment of the wires between patients for prevention of cross infections. Sterilization is the most reliable method of destroying pathogens on wires before reuse. [7], [8]

Copper-nickel-titanium (CuNiTi) archwires are a relatively new tool in the armamentarium of orthodontists. They were introduced in 1994 by OrmcoTM and can be transform between the pliable (martensitic) and the shape-retaining (austenitic) crystalline structures at different temperatures. [9] Thus, they are body heat–activated archwires that are more easily engaged at room temperature and become functional at the temperatures encountered in the mouth. [10]

CuNiTi wires are marketed to orthodontists regarding their different properties, including intermittent force delivery, with various transformation temperatures. They also have a narrower stress hysteresis and more stable transformation temperature and delivery of force. [11], [12], [13] Hence, these wires also aid in the movement of teeth through light continuous force, which avoids hyalinization of the periodontal membrane, necrosis, undermining resorption, and loss of anchorage and decreases the likelihood of root resorption.[14]

When compared to conventional nickel titanium wires CuNiTi develops approximately 20% less loading force. This permits easier engagement in the bracket slot since the wire can be manipulated with less difficultly and it creates less trauma and discomfort to the patient.[14]

Heat–activated archwires that are more easily engaged at room temperature and become functional at the temperatures encountered in the mouth.

Heat-activated NiTi archwires have been introduced with clinically useful shape-memory, low stiffness, high spring-back, and superelasticity of the first and second generation NiTi archwires.[15] According to the scientific basis of the thermo-active wires, an archwire exerting a dynamic load might result to more desirable tissue reaction when compared with an archwire exerting a static load.

Thermoelastic alloys exhibit a thermally induced shape/memory effect whereby they undergo structural changes when heated through a transitional temperature range (TTR).[16], [17] At room temperature the alloy is soft and easily ligated to badly displaced teeth. At mouth temperature the ratio of austenite increases and along with it the stiffness of the wire, so that it more readily attempts to regain the original archform. The extent of this effect depends upon the transitional temperature range (TTR), which can be set specifically by modifying the composition of the alloy or by appropriate heat treatment during manufacture. Temperature rise through the Transitional temperature range produces two effects: increase in the slope of the load/deflection plot and raise in the loading and unloading plateaux. [18], [19] Full recovery on unloading may not always be obtained and has been shown to lie in the range 89–94 per cent.[14]

Recycling involves repeated exposure of the wire for several weeks to mechanical stresses and elements of the oral environment as well as sterilization between uses. The Combined effects of repeated clinical use and sterilization may subject the wire to corrosion and cold working with a resultant alteration in its properties.

Materials and Methods

120 total wires will be taken. 60 wires of copper nickel titanium (ORMCOTM) and 60 wires of heat activated nickel titanium (ORMCOTM). 15 samples as received wires served as controlled group.

The remaining wires were placed intraorally for a period of 4 weeks in patients undergoing orthodontic treatment. After 4 weeks, these wires were taken out. Remaining 45 wires were divided on the basis of sterilization method to be used.

Maximum Load

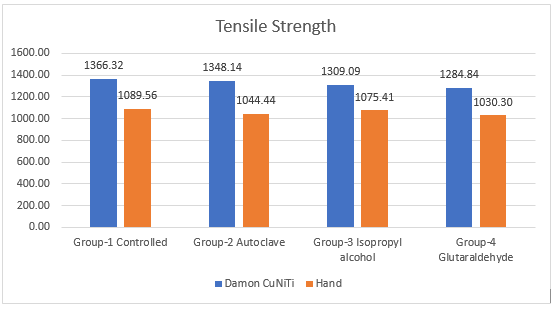

Tensile strength

Results

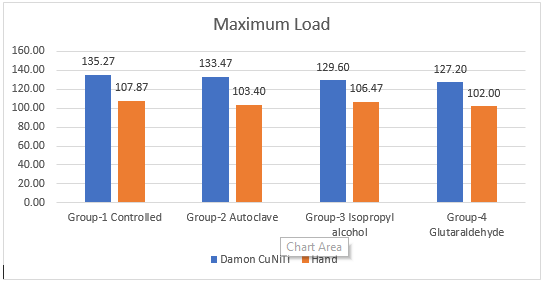

None of the wires demonstrated statistically significant differences in tensile properties and maximum load following various sterilization process. (p value > 0.05).

There no statistically significant difference in mechanical properties of controlled group wires and wires those are placed intraorally for 4 weeks.

The mean value for maximum load of Damon CuNiTi and HANT are shown in [Table 2] and

|

Groups |

No. of wires (Damon CuNiTi /HANT) |

Method of Sterilization |

|

Group 1 |

15 wires |

Controlled group |

|

Group 2 |

15 wires |

Wires sterilized by autoclave method (121 degreecentigrade for 15 minutes at 15 psi) |

|

Group 3 |

15 wires |

Wires sterilized by 70% isopropyl alcohol |

|

Group 4 |

15 wires |

Wires sterilized by 2% glutaraldehyde (10 hr) |

|

Maximum Load (N) |

||

|

|

Damon CuNiTi |

HANT |

|

Group-1 Controlled |

135.27 |

107.87 |

|

Group-2 Autoclave |

133.47 |

103.40 |

|

Group-3 Isopropyl alcohol |

129.60 |

106.47 |

|

Group-4 Glutaraldehyde |

127.20 |

102.00 |

|

Tensile Strength (Mpa) |

||

|

|

Damon CuNiTi |

Hant |

|

Group-1 Controlled |

1366.32 |

1089.56 |

|

Group-2 Autoclave |

1348.14 |

1044.44 |

|

Group-3 Isopropyl alcohol |

1309.09 |

1075.41 |

|

Group-4 Glutaraldehyde |

1284.84 |

1030.30 |

Discussion

The study results revealed that there was no statistically significant difference in the Ultimate Tensile Strength of Damon CuNiTi and HANT wires across different sterilization methods after 4 weeks of clinical use. The finding suggests that both wire types maintain their mechanical integrity under the conditions tested, regardless of the sterilization method employed.

In controlled group of Damon CuNiTi and HANT wires tested as provided by the manufacturer. This allowed for an assessment of any changes in tensile strength resulting from clinical use and sterilization methods. The absence of significant deviations in tensile strength between the controlled group and the clinically used wires further underscores the resilience of both wire types to sterilization processes and clinical conditions.

Ultimate tensile strength (measured in MPa) is the greatest stress an archwire can bear and may vary due to composition and defects in the drawing process. The ultimate tensile strength of the wires used in the study was evaluated using a Universal Testing Machine.

Despite variations in the sterilization methods employed, including autoclave, isopropyl alcohol, and glutaraldehyde solution, the tensile strength of both wire types remained consistent. This suggests that the selected sterilization methods do not significantly affect the mechanical properties of either wire type over the 4-week clinical period.

The study's findings have practical implications for orthodontic practice. Orthodontists often rely on various sterilization methods to ensure the safety and efficacy of orthodontic appliances. The observed consistency in tensile strength across different sterilization methods suggests that clinicians can recycle wires.

The Ultimate Tensile Strength was observed to be highest for controlled group wires (Group 1) as they were tested as given by the manufactures (for Damon CuNiTi is 1366.32 Mpa, for HANT is 1089.56 Mpa).

A reduced tensile strength was observed in Group 2, Group 3, & Group 4 wires when compared to controlled group wires as these wires are kept intraorally for 4 weeks interval, which might have caused some changes.

Ultimate tensile strength was compared between Group 1 (controlled group) and Group 2 (sterilization by autoclave), showed no such significant difference found but ultimate tensile strength of Group 2 wires was slightly reduced than Group 1 wires. Autoclave sterilization might have induced minor changes in the wire properties, contributing to the reduced tensile strength. But there weren’t any significant differences.

Group 3 (sterilization by Isopropyl Alcohol) when compared with the tensile strength of Group 1 wires did not show any significant variance. Group 3 shows slight decrease in tensile strength, suggesting potential effect of isopropyl alcohol on the wire’s structural integrity.

Results of this study were similar to the experiment of Mayhew and Kusy [20] in which they showed no detrimental changes in the tensile properties of 2 nickel-titanium products caused by dry heat and autoclave sterilization.

Stagger[21] showed no significant changes in tensile strength of beta titanium, nickel titanium wire and stainless-steel wire after sterilization by autoclave, dry heat & ethylene oxide involving zero, one a five sterilization cycles. It is similar to the results of Lee [22] in which he found no significant changes in mechanical properties, surface topography & frictional forces of three types of nickel titanium wires after recycling.

Pernier [23] found that autoclave sterilization had no adverse effects on surface parameters and mechanical properties of six types of wires currently used in orthodontics.

Sayed [24] compared influence of 2 type of sterilization/disinfection procedures (autoclave & hydrogen peroxide) on tensile strength and surface topography of 2 orthodontic wires (NiTi and CuNiTi) and non-significant results found.

Lowest tensile strength was shown in Group 4 wires which is sterilized by glutaraldehyde solution (for Damon CuNiTi is 1284.84 Mpa, for HANT is 1030.30 Mpa). But mean result did not show any significant difference. When compared with Group 1 wires, they showed slight reduction in tensile strength.

Similarly, Smith [25] found no significant difference in wire strength of new and used wire (nickel-titanium, Beta titanium and stainless steel)

Crotty [26] examined the effect of currently used infection control procedures (autoclave and 2% glutaraldehyde solution) on mechanical properties of superelastic Mekel titanium alloy and found that there were no statistically significant differences. Although there was slight decrease in tensile strength.

When Group 3 and Group 4 is compared to the Group 2 wires, there is no such significant difference found in tensile strength of wires.

Results are similar to the study done by Oshagh, [27] they found nonsignificant differences in mechanical properties of wire sterilized by autoclave and isopropyl alcohol.

The Autoclave sterilization technique, well known for its effectiveness in sterilization, outperformed Isopropyl Alcohol & Glutaraldehyde Solution in effectively sterilizing and recycling Orthodontic wires.

The tensile strength of Group 4 wires exhibited lower levels compared to Group 3 wires, however, no statistically significant difference was observed. Prolonged immersion of wire in Glutaraldehyde Solution might have resulted in a reduction of tensile strength.

For years, clinicians have been saying that the performance of recycled nickel-titanium was clinically acceptable. The results of this investigation add scientific credence to that position. These wires were subjected to various malocclusions, clinician handling techniques, and different sterilization/disinfection protocols. Yet there is no overall clinically significant difference in new versus used wires.

It is possible that the differences we found in force production are due to the interactions of bracket and arch wire geometry, and uneven distributions of strain hardening within the wire that result from the manufacturing process.

Changes in the tensile strength will have a direct impact on the clinical use of wires. If a wires ultimate tensile strength is decreased, it is more prone to breakage which presents a problem for patient and the orthodontist alike.

A common reason given for not recycling wire is fear of reducing wire strength, this study showed that wire strength is not reduced significantly after recycling.

The stability of tensile strength across different sterilization methods enhances the versatility of these wires in orthodontic practice and provides clinicians with flexibility in selecting appropriate sterilization protocols.

Conclusion

This study demonstrates that following a 4 week period of clinical use, there exists no statistically significant difference in Ultimate Tensile Strength of Damon CuNiTi and HANT wires subjected to various sterilization processes including Autoclave, Isopropyl Alcohol, and Glutaraldehyde solution. The comparison of sterilized wires with the control group wires found statistically non-significant difference in Ultimate Tensile Strength.

By assessing the tensile strength after recycling, suggests that wire is efficient in maintaining its properties. Tensile strength tests can also provide insights into efficacy of the orthodontic wire in achieving desired treatment outcome, as wires maintains its tensile strength after clinical use & sterilization.

The results emphasize the durable mechanical strength of both wires under various sterilization methods, underscoring their appropriateness for orthodontic reuse. Further research is needed to validate its clinical application.

Source of Funding

None.

Conflict of Interest

None.

References

- S Kapila, R Sachdeva. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofac Orthop 1989. [Google Scholar]

- E Atik, HG Coskuner, BA Guven, T Taner. A comparative assessment of clinical efficiency between premium heat-activated copper nickel-titanium and superelastic nickel-titanium archwires during initial orthodontic alignment in adolescents: a randomized clinical trial. Prog Orthod 2019. [Google Scholar]

- RC Sachdeva, S Miyazaki. Farzin-Nia F, inventors; Ormco Corp, assignee. Orthodontic archwire and method of moving teeth. United States patent US. 1991. [Google Scholar]

- A Yadav, K Poonam, R Jayaprakash, M Singh, P Dawer, B Modi. Impact of recycling on the mechanical properties of nickel -titanium alloy wires and the efficacy of their reuse after cold sterilization. J Orthod Sci 2020. [Google Scholar]

- JE Buckthal, RP Kusy. Effects of cold disinfectants on the mechanical properties and the surface topography of nickel‑titanium arch wires. Am J Orthod Dentofac Orthop 1988. [Google Scholar]

- RP Kusy. A review of contemporary archwires: their properties and characteristics. Angle Orthod 1997. [Google Scholar]

- M Brindha, NK Kumaran, K Rajasigamani. Evaluation of tensile strength and surface topography of orthodontic wires after infection control procedures: An in vitro study. J Pharm Bioallied Sci 2014. [Google Scholar]

- MJ Mayhew, RP Kusy. Effects of sterilization on the mechanical properties and the surface topography of nickel-titanium arch wires. Am J Orthod Dentofac Orthop 1988. [Google Scholar]

- FJ Gil, JA Planell. Effect of copper addition on the superelastic behavior of Ni-Ti shape memory alloys for orthodontic applications. The Japanese Society for Biomaterials, and The Australian Society for Biomaterials and the Korean Society 1999. [Google Scholar]

- MC Biermann, DW Berzins, TG Bradley. Thermal analysis of as-received and clinically retrieved copper-nickel-titanium orthodontic archwires. Angle Orthod 2007. [Google Scholar]

- T N Bartzela, C Senn, A Wichelhaus. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthod 2007. [Google Scholar]

- S Kapila, R Sachdeva. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofac Orthop 1989. [Google Scholar]

- C Matthew, David W Biermann, Thomas Gerard Berzins, Bradley. Thermal Analysis of As-received and Clinically Retrieved Copper-nickel-titanium Orthodontic Archwires. The Angle Orthod 2007. [Google Scholar]

- Farnaz Parvizi, W P Rock. The load/deflection characteristics of thermally activated orthodontic archwires. Eur J Orthod 2003. [Google Scholar]

- M A Gravina, C Canavarro, C N Elias, Mgam Chaves, Ihvp Brunharo, Cca Quintão. Mechanical properties of NiTi and CuNiTi wires used in orthodontic treatment. Part 2: Microscopic surface appraisal and metallurgical characteristics. Dental Press J Orthod 2014. [Google Scholar]

- N Babanouri, M Sarbaz, Y Alamdarloo, M Haghighat, S Ajami. Comparison of the mechanical properties and surface topography of as-received and as-retrieved Copper-Nickel-Titanium arch wires: An ex-vivo study. Int Orthod 2023. [Google Scholar]

- S E Bishara, J M Winterbottom, A H Sulieman, K Rim, J R Jakobsen. Comparisons of the thermodynamic properties of three nickel-titanium orthodontic archwires. Angle Orthod 1995. [Google Scholar]

- T G Bradley, W A Brantley, B M Culbertson. Differential scanning calorimetry (DSC) analyses of superelastic and nonsuperelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop 1996. [Google Scholar]

- M Santoro, O F Nicolay, T J Cangialosi. Pseudoelasticity and thermoelasticity of nickel-titanium alloys: a clinically oriented review. Part I: Temperature transitional ranges. American Journal of Orthodontics and Dentofacial Orthopedics 2001. [Google Scholar]

- G A Smith, Von Fraunhofer, J A Casey, G R. The effect of clinical use and sterilization on selected orthodontic arch wires. Am J Orthod Dentofac Orthop 1992. [Google Scholar]

- J A Staggers, D Margeson. The effects of sterilization on the tensile strength of orthodontic wires. Angle Orthod 1993. [Google Scholar]

- S H Lee, Y I Chang. Effects of recycling on the mechanical properties and the surface topography of nickel-titanium alloy wires. Am J Orthod Dentofac Orthop 2001. [Google Scholar]

- C Pernier, B Grosgogeat, L Ponsonnet, G Benay, M Lissac. Influence of autoclave sterilization on the surface parameters and mechanical properties of six orthodontic wires. Eur J Orthod 2005. [Google Scholar]

- Y Sayed, K Aboulazm, A Fahmy. Evaluation of ultimate tensile strength and surface roughness of NiTi and CuNiTi orthodontic archwires after recycling procedures. Egyptian Orthodontic Journal 2018. [Google Scholar]

- G A Smith, Von Fraunhofer, J A Casey, G R. The effect of clinical use and sterilization on selected orthodontic arch wires. Am J Orthod Dentofac Orthop 1992. [Google Scholar]

- M Oshagh, M R Hematiyan, Y Mohandes, M R Oshagh, L Pishbin. Autoclaving and clinical recycling: Effects on mechanical properties of orthodontic wires. Indian J Dent Res 2012. [Google Scholar]

- O P Crotty, E H Davies, S P Jones. The Effects of cross-infection control procedures on the tensile and flextural properties of superelastic nickel-titanium wires. Br J Orthod 1996. [Google Scholar]